Manufacturing Brands.

Our technology revolves around cases and molded parts. We manufacture and sell our own brands and at the same time are partners for internationally successful brands. Here we act as a contract manufacturer and produce and develop products together with our customers. Our core competencies lie in the areas of shaping, cutting and transforming. We have different technologies and materials for this, especially in the area of recycled and bio-based materials.

Shape

Cut

Transform

Applications

-

Formfleece

Formfleece PartsWe produce 3D molded fleece parts using the compression molding process. In this process, a fleece is heated and pressed into shape using tools. We develop and process different types of nonwovens made from polyester, natural fibers, upcycling and viscose.

-

Plastic Moldings

Molded Plastic PartsWe manufacture plastic parts using the thermoforming process. Here we focus on the thermoforming or vacuum forming of sheet materials. Depending on the application, the sheet materials are made from a wide variety of plastics and are usually tailored to the end product.

-

Specialty Bags

Specialty BagsWe manufacture a wide variety of specialty bags and are experts in a wide range of sewing processes. The bags we produce range from fashionable bags for sporting goods to highly technical bags with specific fabric and load requirements.

-

Specialty Cases

Specialty CasesWe manufacture special cases on the basis of our production processes. A case is two molded parts that are technologically matched to each other. The interior of a special case is very important, and we have a wide range of solutions for interior fittings and inserts.

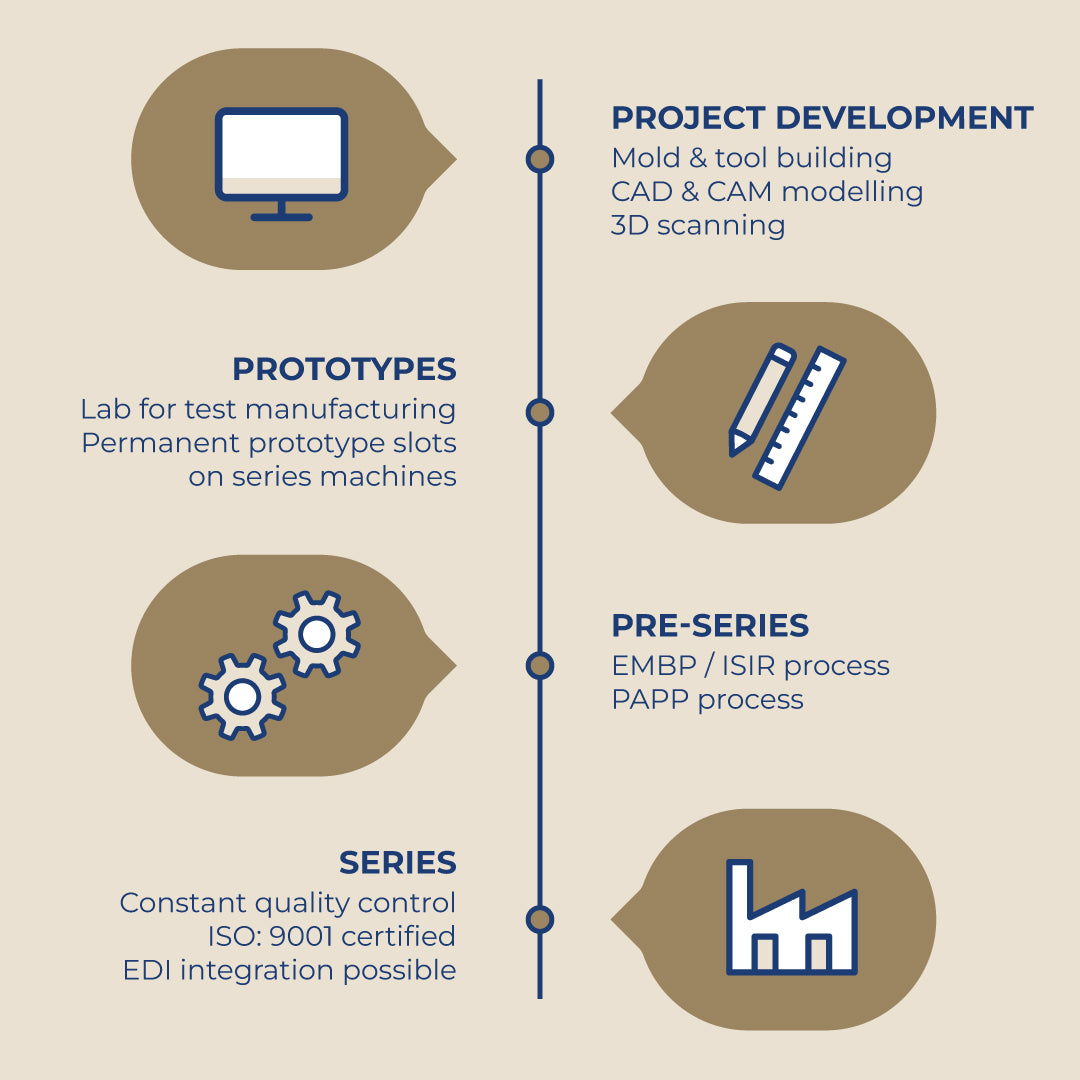

Competencies

We work as a supplier for a wide range of customers - from small companies to large corporations. We generally adapt to the requirements of our customers and can cover everything from simple and fast product developments to complex development steps.

Research and Funding

We are constantly researching new developments. Our team of developers goes beyond the status quo and explores new ways of manufacturing our products.