Foam Inserts and Packaging

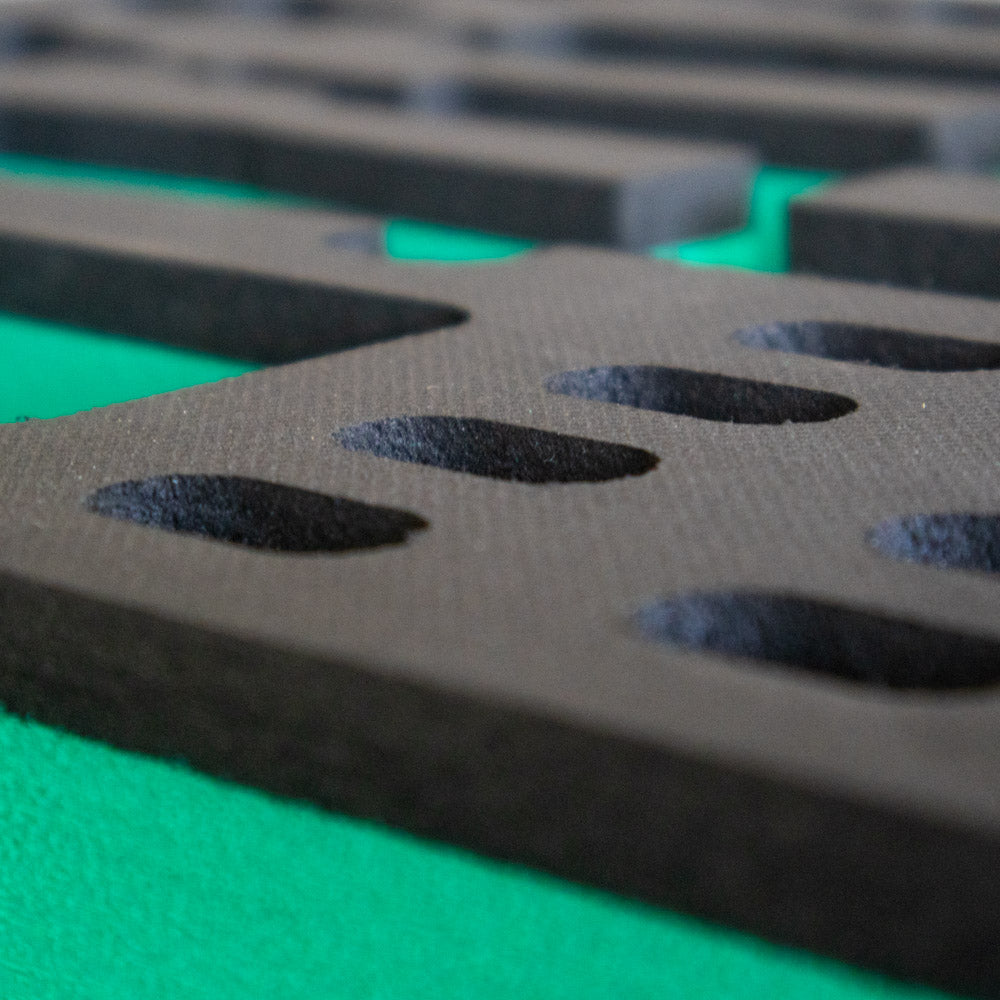

We achieve the necessary precision and form fit using modern CNC milling machines. The advantage of this process is its cost efficiency, as no tools are required. Programming the milling machine takes little time and the process itself is almost completely automated.

Possibilities for Processing

We mill most of our foams to create precisely fitting molded parts and inserts. In addition, it is also possible to process the material with a water jet cutter in order to achieve a specific edge finish, for example. As a third option, we also work with hydraulic die-cutting machines, which can also be used to process foams.

Application for Foam Packaging and Inlays

The areas in which foam is used are as diverse as the materials and their properties. Inserts, packaging and inlays made of foams can be used in countless industries, and individual processing using milling machines sets almost no limits to the end product. We are fully familiar with the respective material and cutting pattern requirements.

Transport

Suitcases, flight cases, etuis, containers, cardboard boxes - foam inlays guarantee the safe transportation of a wide variety of items. Precisely fitting inserts and durable material also provide optimum protection for sensitive accessories on long journeys.

Presentation

For presentations at trade fairs or customer pitches, made-to-measure inserts are ideal for conveying care and quality. The products are optimally protected and attractively presented at the same time. The foam inserts can also be used as advertising material or in product displays for high-end products such as watches and jewelry, as they can be elegantly laminated with various materials. The choice of antistatic ESD foam is particularly worthwhile for the presentation of electrical devices such as cameras or smartphones.

Drawer Inserts and Organisation

Foam inlays are a good choice to ensure that everything is in the right place at the right time. They can be used in drawers or cupboards for simple applications such as desk organization or for complex logistics optimization. Various utensils can thus be stored in the best possible way, whether in the office to keep the workplace perfectly organized or in the catering trade to keep cutlery and kitchen utensils to hand, to name just a few examples.

Pads and Protective Mats

As a resistant and durable material, PE foam is also suitable for tasks with high loads. The material can be used as a support or protective mat in many areas. Foam is also suitable for such applications thanks to its resistant and durable structure, which also offers softness and elasticity. For example, foam is used in occupational safety or as a protective base for construction components.

Foam Packaging and Specialty Accessories

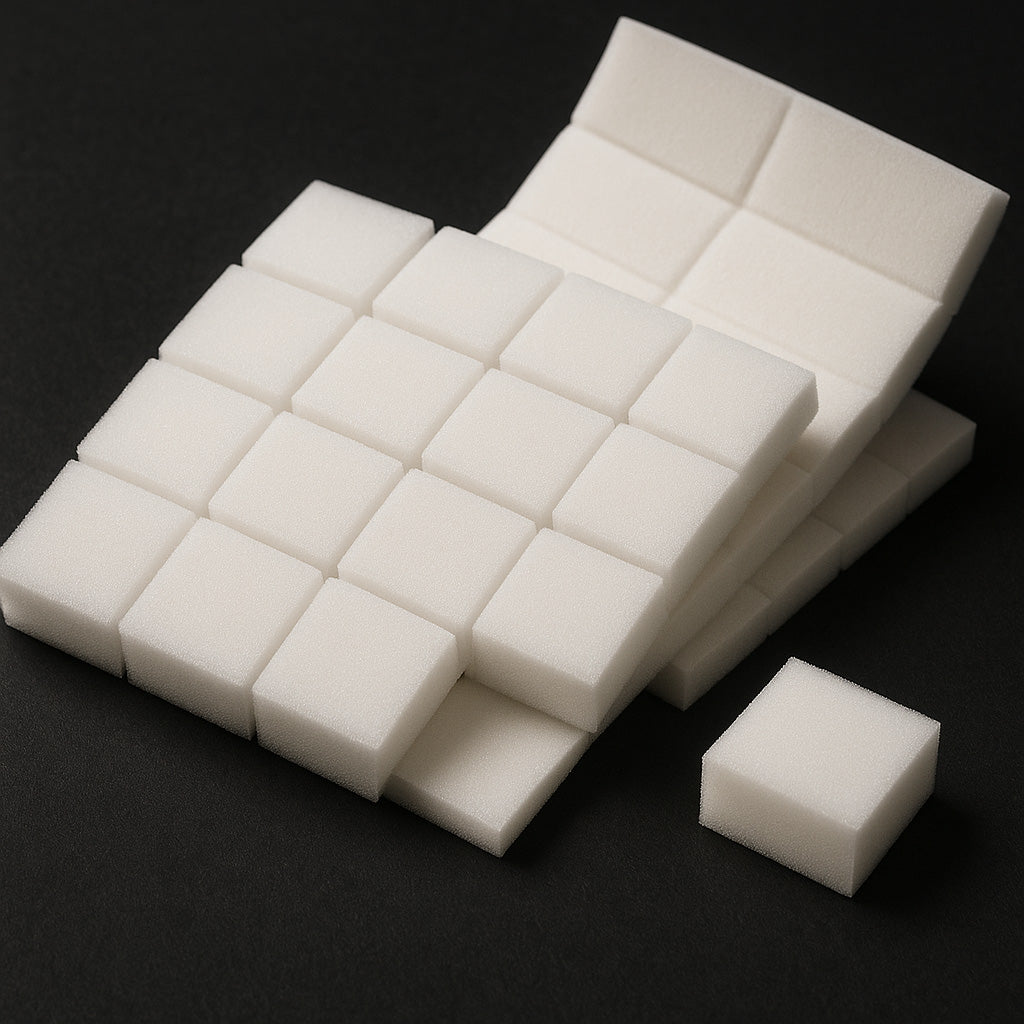

Foam packaging can take various forms to ensure protection against shocks and vibrations. Constructive packaging is particularly suitable for sensitive objects that need to be completely enclosed in a protective shell during transportation. Interlocked, glued or made from one piece, the foam surrounds the object on several sides to absorb shocks during transportation as effectively as possible. Antistatic foams with ESD protection are particularly suitable for electrical appliances such as TVs. In small format, distance pads can be used to place them between less sensitive components to prevent them from bumping into each other.

Application in Soundproofing

The strong insulating properties of foams also make them ideal for sound insulation. Recycled foam in particular is especially suitable for reducing noise due to its usually higher density. Foam panels are used in machine and engine housings or specific rooms, such as recording studios, large halls or even home cinemas. Currently, its use in the energy sector is also becoming increasingly important: for example, for the insulation of heat pumps, seals for electric charging stations or the noise insulation of wind turbine gearboxes.

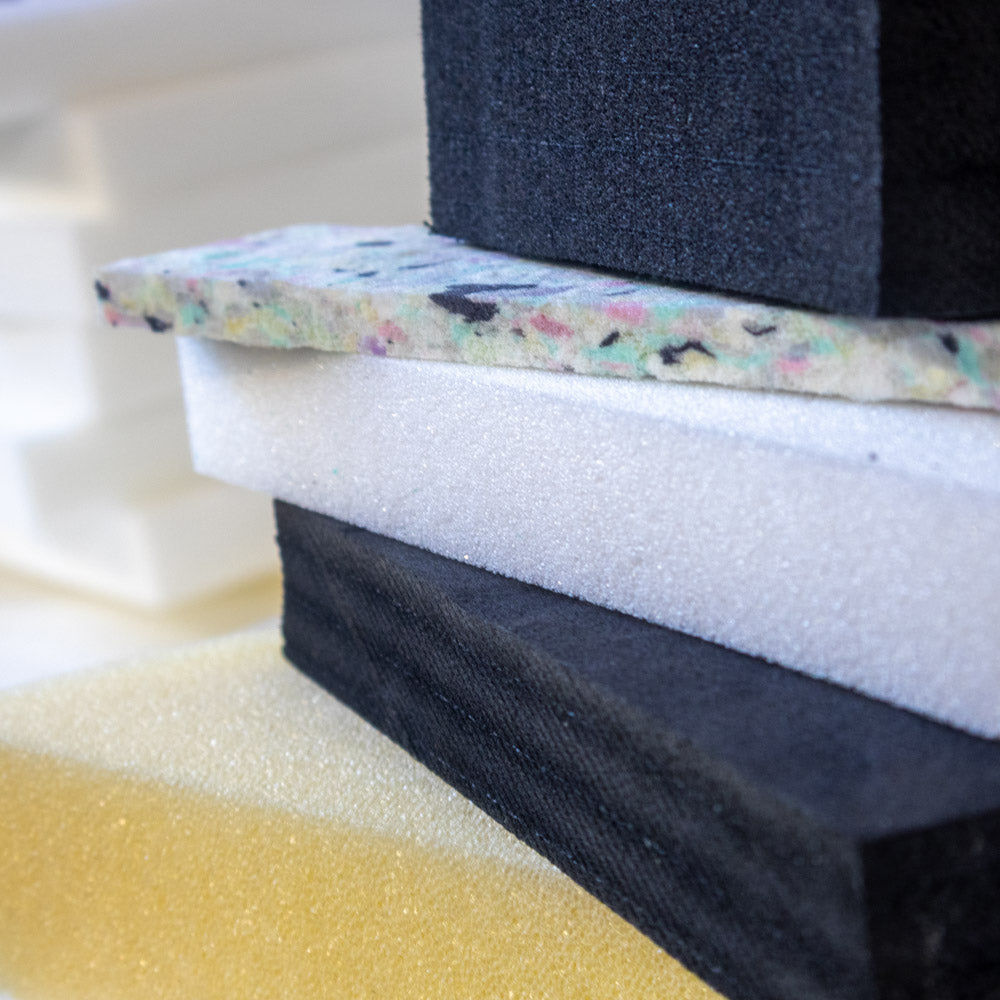

Foam Materials for Inlays

Polyethylene Foam (PE)

This closed-cell foam is probably the best-known option for packaging and cushioning material. Polyethylene is very strong and dense. This makes it suitable for durable cushioning and the transportation of heavier items. PE foam is also strong in thermal insulation and resistance to chemicals. Various special processing options are available to equip the material for special applications: antistatic, electrically conductive, flame-retardant, self-adhesive and other properties can be implemented.

Polyurethane Foam (PU)

This versatile, open-cell foam usually has a softer and more flexible structure. Depending on the density and area of application, the thermal insulation of flexible PU foam or the stronger mechanical properties of rigid foam may be preferred. There is also a distinction between ether-based foam (particularly insulating and water-resistant) and ester-based foam (resistant to light chemicals such as oils or soaps).

Crosslinked PE Foam

Crosslinked PE foam is one of the most widely used materials for packaging and cushioning. Compared to its non-crosslinked counterpart, the material is even stronger and more durable. It is also characterized in particular by high thermal insulation and resistance to liquids. This makes the material particularly suitable for demanding applications and transportation. Just like non-crosslinked PE, crosslinked PE can be processed in different ways, for example to achieve antistatic properties.

Recycling and Compound Foam

Despite the fact that foams are almost always made of plastic, there are sustainable options here too. Recycled foams consist of offcuts from conventional foams that are joined together to form new sheets. The material itself is also easily recyclable and can be reused several times. The recycling process usually gives the material a higher density, making it harder and more stable and providing good sound and vibration damping.

Biobased Foam

In order to make the production of foam as sustainable as possible, biobased resources can be used. These replace a certain percentage of the plastic content in the foam and thus reduce the impact of fossil raw materials. Substitutes can be sugar cane or vegetable oils from rapeseed, for example.

Your Project

Our work is far from finished with a completed foam insert. We supervise projects from the first sketch through to assembly - complete solutions for cases and molded parts are our specialty. We take care of the selection and procurement of materials, the creation of cutting patterns and the shipping ourselves, or work together with your own experts to optimally fulfill your needs.