Upcycling Fleece

Our standard nonwoven is made from clothing waste and a recycled matrix fiber. The material is circular and can be recycled in a closed loop (mechanically).

Upcycling Textiles

3D Shaping

Upcycling fleece can be formed into 3D molded parts and is a substitute material for various other materials, especially polyester fleece. For example, it can replace metal parts such as cable trays or fabric-covered products such as screens. Chair shells, storage boxes, partition walls and many other products can be made from upcycling fleece.

Upcycling Textiles

Sheet Materials

We supply standard materials, but our real strength lies in producing customized solutions. We can customize the grammage, thickness and size of the sheets freely.

- Our standard thicknesses are 10mm, 12mm (2,000 g/m2) and 20mm (3,000 g/m2). Individual thicknesses of 3-30mm and grammages from 1,000gsm to 4,000gsm are possible.

- Our standard sizes are 3,200mm x 2,200mm and 2,300mm x 1,200mm, depending on the material and color. Individual sizes are readily available from us at any time.

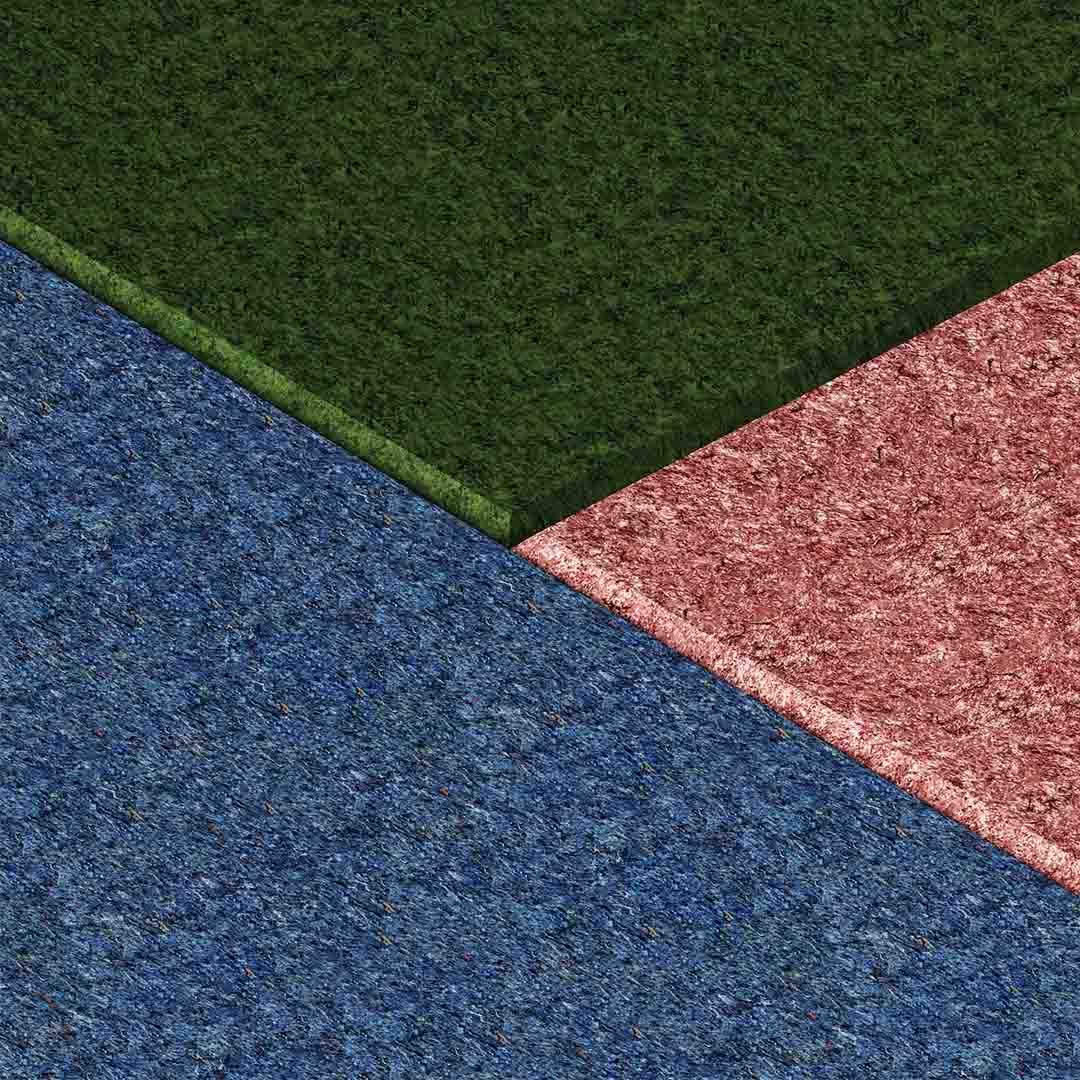

Standard Color Collection

Upcycling Your Textile Waste

We can use not only clothing as the basis for an upcycling fleece, but also textile production waste or remnants. Even textiles with foam or composite textiles can be used. If the textiles are made of polyester and are unmixed, we can even produce a certified polyester mono-material fleece from them. Certifications such as Oeko-Tex are also possible.

Circular Options for Textile Waste

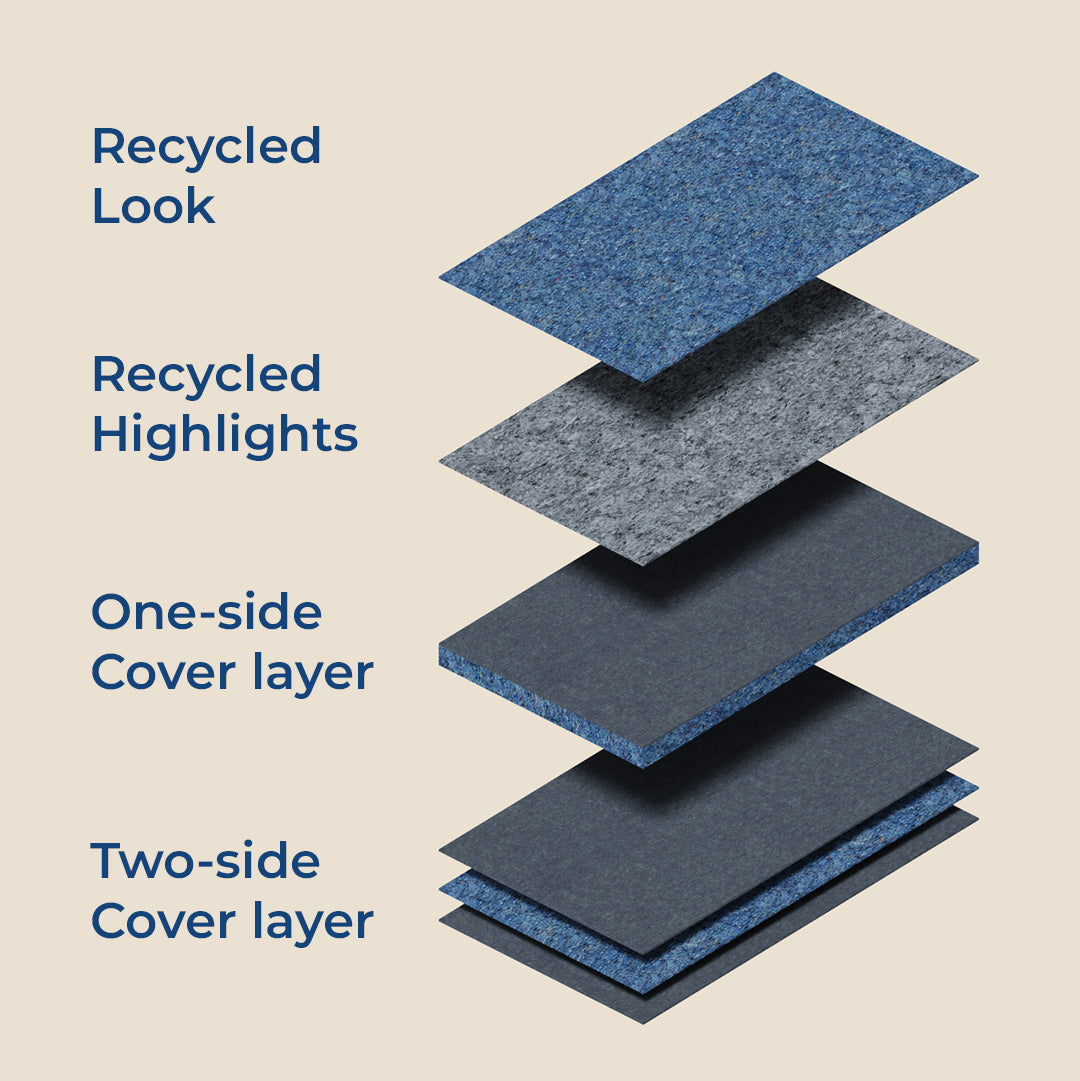

Different finishes can be achieved through various recycling processes and the individual processing of the upcycled fleeces. The original appearance of the textiles can be retained, or a certain percentage can be mixed with regular nonwovens to create highlights. In addition, the textiles can be fully covered and pressed with a thin layer of other polyester nonwovens so that they are no longer visible from one or both sides.

Clothing Waste Becomes Fibers

To transform clothing waste into recycled fibers, discarded textiles are collected, sorted by type and torn into small pieces. These fibers are then processed into a fleece, giving them a new life as high-quality furniture and acoustic components. Nowadays, there is no end-of-life concept for most clothing waste and it is usually incinerated or ends up in landfill sites.